The easiest way is to use the factory service manual wiring diagrams, if you trace the circuit it will tell you the connector part number. Installation to a panel uses a single-action method on the anchored side and a floating screw structure on the floating side which permits smooth insertion and disconnection without forcing.I've been relatively successful at figuring out Toyota OEM and mating connectors as well as the Sumitomo, Yazaki (in Japan) and sometimes Tyco or Delphi equivalents. Two sequential contacts in the signal male unit and one sequential contact in the power supply female unit are provided for safety operation. The power supply terminals permit the use of a crimp harness using wire of AWG#16 to 18 (and insulation outside diameter of 2.1 to 2.2mm), and can accommodate a maximum of 12 A. (The wire is AWG #26 and the insulation outter diameter is 0.88mm.) The insulation displacement procedure can now be used by attaching a special applicator to a commercially available automatic insulation displacement machine, or a manual press tool can also be selected. The signal unit uses the highly reliable insulation displacement connection method. In order to improve the harness procedures, the connectors are designed for the complete segmentation of the external holder and the signal/ power supply unit, and inserting the harnessed contacts aims to improve the workability of the power supply/signal line harness as well as the mounting to the set. Completely separated structure of the external holder/terminal unit These connectors are configured with 12, 18, or 24 pos.(IDC) in the signal line, and 4 pos.(crimp) in the power line.ġ.

#Connector housing series

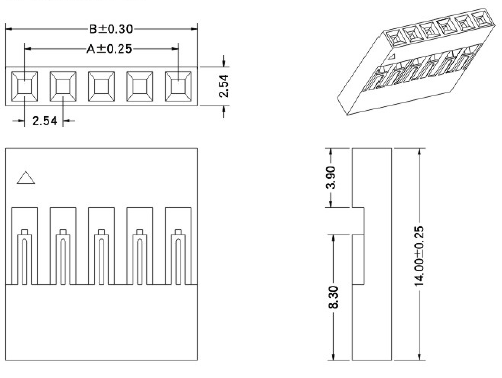

The QR/P18 Series of miniature rack/panel connectors is designed for the complete segmentation of the structure of the external holder/terminal units of the well-received QR/P Series of plug-in rectangular rack/ panel connectors furthermore, the subsequent insertion of the harnessed terminal unit affords a more efficient harness mounting task. Rectangular, High-Pin-Count Rack/Panel Insulation Displacement Connectors (IDC) Reliable connections Two-point contacts assure highly reliable electrical and mechanical connection. Wire termination can also be accomplished with an automatic crimping machine.Ĥ.

The power supply connections use an MDF6 Series 4-position connector (3.5mm pitch, UL and CSA recognized, and can handle 6A a current using 16 AWG conductors. Accepts power supply connections (24-position only) The 24-position connectors incorporate power supply contacts. This provides better grounding and improved safety.ģ. Sequential contact mating structure Sequential contact mating is featured on the 40-position version, with two contacts on each side of the connector.

This separate structure of a main connector body and sub-assemblies allows harnesses to be preassembled, and simplifies the installation of both the sub-assenblies and rack and panel mounting.Ģ. Two piece part structure The main connector body is not directly terminated with individual or discrete wires, but allows for cabled, sub-assembly connector groups to be plugged and unplugged to it. Available in 8 or 24 pos (with 4 positions for power contacts) and 40 pos.ġ. Plugs / receptacles can be mounted on the panels and the terminated connectors may be inserted at later time, allowing wire crimp termination to be done away from the equipment. Expansion of the proven QR/P Series with a separate panel-mounted plugs / receptacles connecting with detachable crimp terminated connectors.

0 kommentar(er)

0 kommentar(er)